Let's talk about printing!

Methods, processes, & advantages

Digital Printing

Process

This super high quality, printing process is printed directly from a digital file & does not require plates. It can achieve myriad colors by transferring four ink colors (cyan, magenta, yellow & black (CMYK)) to paper all at one time! Digital printing produces a flat image, without any texture (unlike letterpress or foil stamping which use a plate to create a relief impression). Since all four colors are simultaneously, the printing process is fairly quick & because it does not require plates to transfer the ink to the paper it is the most economical printing process, especially for smaller quantities. You can also combine digital printing with letterpress & foil stamping for the best of both the flat & impressed printing worlds!

COST

$ - Most economical choice if your palette includes more than 2 colors

YAYS

• Ability to print a multitude of beautiful, rich, crisp colors

• Great for suites that incorporate multicolor watercolor designs, patterns or illustrations

• All colors print at the same time, instead of layer by layer like other printing processes

• Looks gorgeous on smooth or cotton paper

• No photo-polymer or metal plates are required

• You can request full color digital proofs, on exact paper you’ve chosen

- which is great because you can see exactly what you are going to get before your entire suite is printed!

• Great for double sided designs

Things to think about

• Cannot print white

• Cannot print metallics

• Cannot print on dark, super thick or super textured papers

• Prints CMYK not pantones

Letterpress Printing

History

Back in the day, monks & other scribes would physically draw the all of the fonts, illustrations, details & designs of books & publications by hand...every time! Hints why there are not a lot of books from wayyy back when! Then with the invention of letterpress (in approx 1500 AD!) blocks were created for individual letter-forms that were put together to create words & allowed them to be printed time after time. Yay! The final product is so gorgeous & a labor of love. Wedding invitations have been printed with the letterpress method since around 1800!

Process

So how does it work? Some specialty letterpress shops still use old wooden or metal move-able type, but now a days most use photo polymer plates because they allow you the freedom to create the perfect design & spacing! To create the plates first a digital design is created (we often create the original design by hand then scan them into the computer) then printed on film paper as a negative. Then the film is exposed to light onto a polymer plate & where the light comes through the plate hardens & the rest is washed off. Think of it like this. Hold your hand up to a light & you’ll see a shadow on the ground. Now spread your fingers & see that where your fingers are separated the light shines through to the ground - this is the part the becomes raised on the plate & indented your paper. Every color you use requires its own plate & is printed one at a time! Plate sits in the press bed & awaits inking!

Large metal rollers are then inked, one color at a time, & rolls over the plate. Then paper is inserted into the press, the wheel is cranked & the force of the machine rolling the paper on to the plate, paper actually gets pushed down, where the design is on the plate, and you are left with an imprint that leaves a debossed texture on the paper! Think about if you use a fork to lightly poke play dough, you are left with a lowered texture where the fork poked. Repeat the whole process for as many colors as you have with careful testing for registration (alignment & placement). Once all the colors are dry each piece is trimmed to scale and voila! You have your design! You can also combine letterpress with digital printing, foil stamping or screen printing for an extra level of beautiful!

Cost

$$ - Costs more than digital printing

Yays

• Its a gorgeous way to blend a classic printing method with a modern design

• Great option if you want your suite to have a beautiful debossed impression/texture

• Can print almost all colors except white

• Can print metallic colors, HOWEVER though they appear flat with a slight shimmer & transparent, not opaque & shiny like foil stamping

• Can print on a variety of beautiful paper colors, though darker paper colors may be more difficult to read as the ink is transparent

THINGS TO THINK ABOUT

• Requires one plate per color

• Best for 1-3 color designs

• Slightly longer turn around time than digital printing

• Must use caution when using letterpress for a double sided design

- In order for the design to not show through to the other side either a lighter impression must be used or a super thick paper

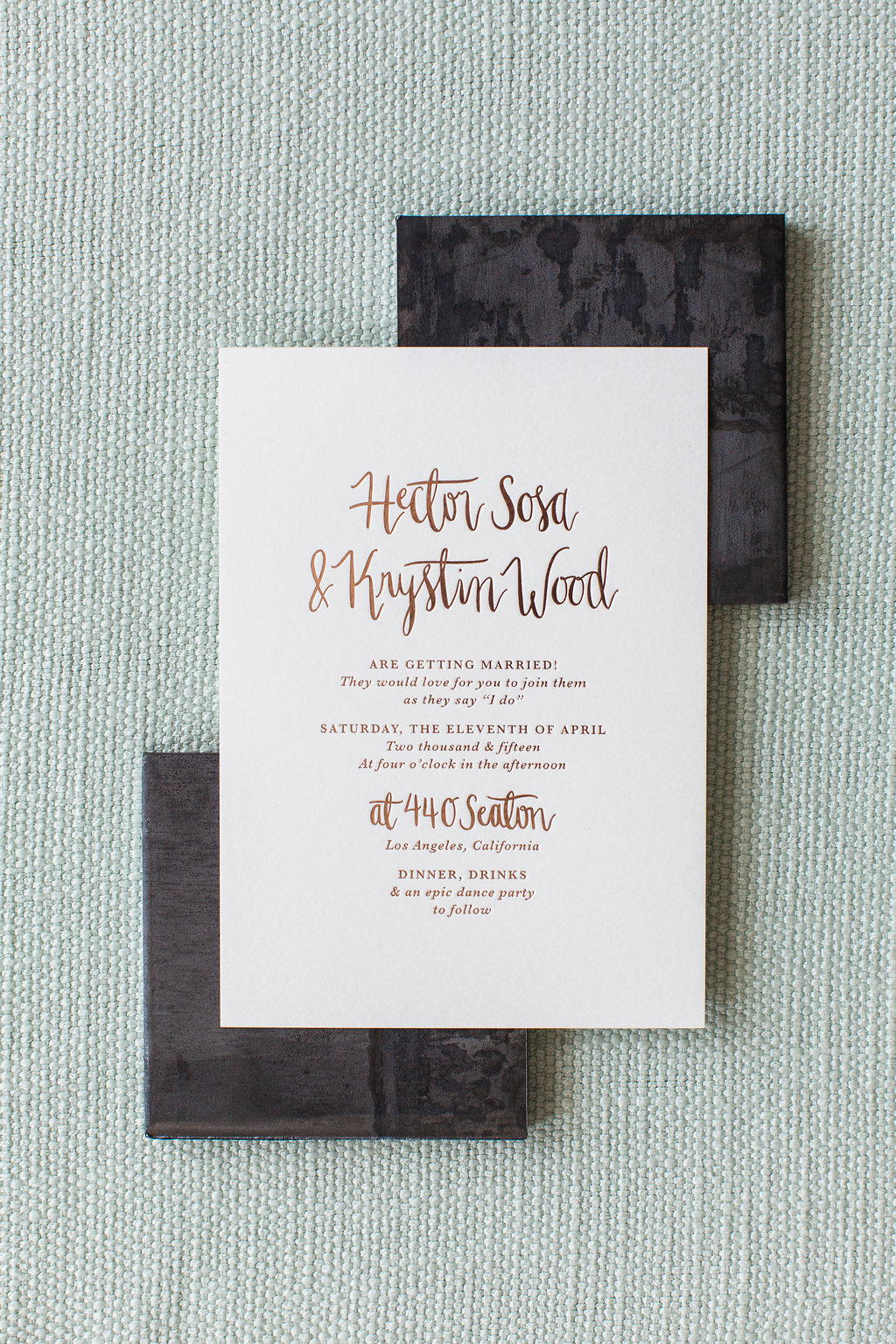

Foil Stamping

Process

This process issimilar to letterpress, in that designs are done one color at a time & leave a beautiful impression. However instead of photo polymer plates magnesium dies are made & heated up for stamping. And instead of ink a thin sheet of foil is pushed into the paper with the heated magnesium die & with lots of pressure the foil is transfered to the paper. Its also awesome to combine this technique with either letterpress or flat printing to get an added burst of color :)

Cost

$$$ - Costs more than digital & letterpress printing

Yays

• Best option for metallic & design

• White looks gorgeous too!

• The foil comes in a variety of colors & finishes (matte, shinny..etc)

• Great option if you want your suite to have a beautiful debossed impression/texture

THINGS TO THINK ABOUT

• Requires one plate per color

• Best for 1 color designs

• Slightly longer turn around time than digital printing

Screen printing

Process

Also know as silk screening, this beautiful process dates wayyyy back to the Song Dynasty in China! For this process, digital design is printed on to a sheet of film but instead of a negative image like what is used for letterpress, this uses a positive image. This film is exposed onto a screen which is coated with a light sensitive emulsion. Like plates in letterpress, each color in a screen printed design requires a different screen. Then ink is pulled through the tiny holes in the screen & transfers the design onto the paper or fabric!

Cost

• $$ - Costs about the same as letterpress printing

Yays

• Awesome for light ink on dark paper

• Great for thick papers

• Great for fabric, wood & other alternative materials

THINGS TO THINK ABOUT

• Requires one screen per color

• Best for 1-3 color designs

• Not a great option for super small text or super tiny details

• Large blocks of color are hard to print consistently and will oven have a textured looking effect to them

(which can actually be a beautiful good thing if you are aware of & want that to happen!

• Slightly longer turn around time than digital printing

• Should not be used with double sided designs

Hand-stamping

Process

For hand stamps a digital design is created which is then turned into a rubber stamp (with or without a handle). The stamp is then blotted with an ink pad & stamped onto the paper/fabric/wood to transfer the design. Because of registration concerns, stamps should almost always only be used for one color designs.

Cost

$$$ - Costs about the same as foil printing (unless it is just for addresses on envelopes)

Yays

• Awesome for white ink on dark paper

• Great for thick papers

• Great for fabric, wood & other alternative materials

THINGS TO THINK ABOUT

• Very labor intensive & takes a long time

• Registration even with one color can be difficult

• Best for 1 color designs

• Not a great option for super small text or super tiny details

• Large blocks of color are hard to print consistently and will oven have a textured looking effect to them

(which can actually be a beautiful good thing if you are aware of & want that to happen!

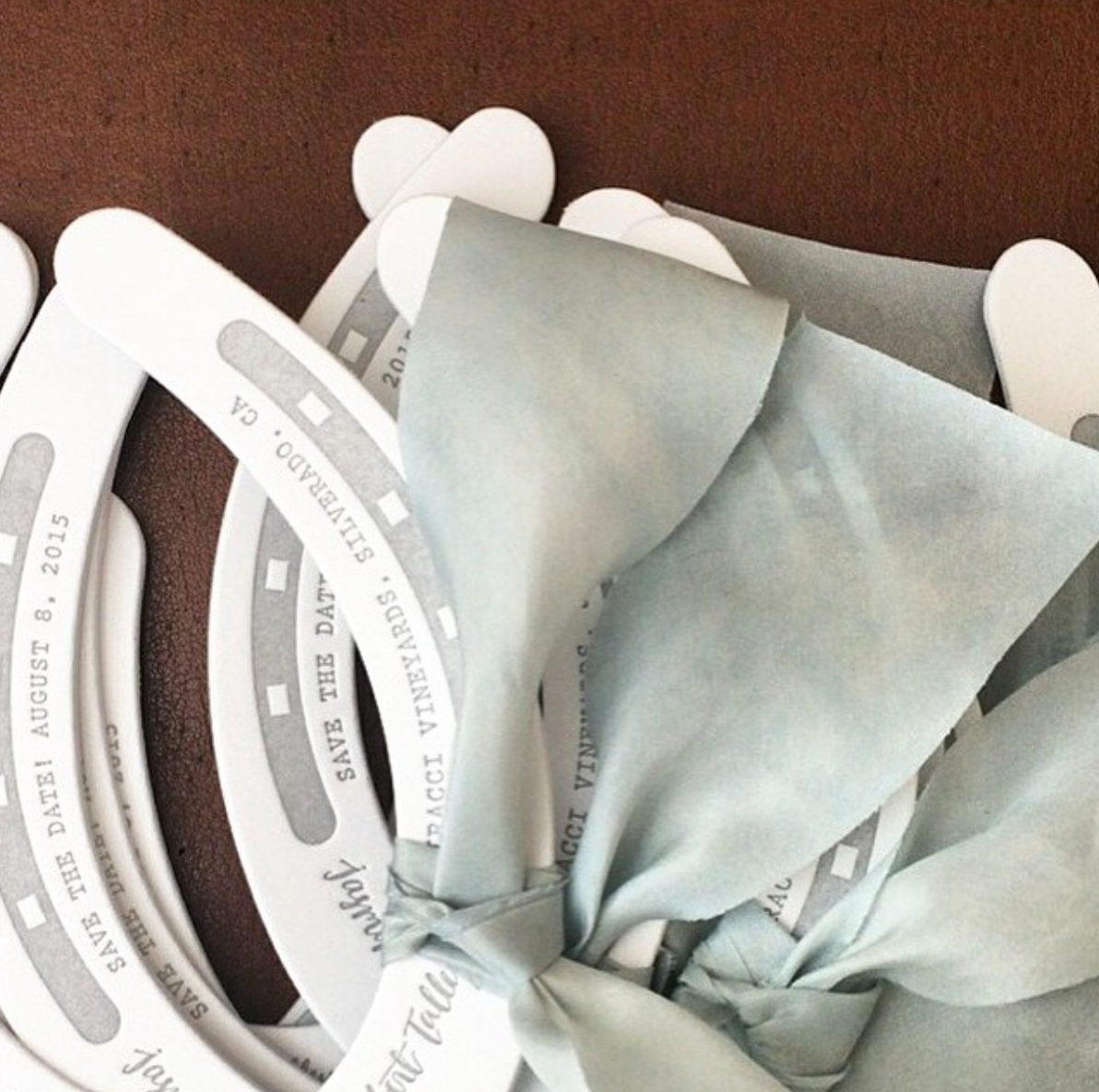

Laser engraving & cutting

Process

With laser engraving a laser is used to precisely etch away a material, creating a debossed effect. With laser cutting a laser is used to cut materials into specifically designed shapes.

Cost

$$$$ - Cost varies significantly depends on size, material & complexity & cutting vs engraving

Yays

• Engraving - Great for using on alternative materials, invitations, tags & gifts

• Cutting - Great for cutting fun shapes

THINGS TO THINK ABOUT

• Burn marks can be left on the design, especially paper, thus often times wood will be stained or painted to cover marks

- burn marks can also be beautiful if that is your intended design

Header photo by Ashley Kelemen